(Sample drone illustration by PSH Design)

Mastering Drone Hardware: Top Design Challenges and How to Overcome Them

Table of Contents :

- Introduction :

- Key Challenges in Modern Drone Hardware Design

- Optimizing Weight – Durability – Performance

- Limitations of Battery and Power Sources

- Payload Capacity and Modular Flexibility

- Sensor and Control Circuit Reliability

- Production Costs – Design Freedom – Scalability

- Stability of Drive Systems

- Future Solutions and Innovations in Materials and Technology

- New Materials and Advanced Manufacturing

- Next-Generation Battery Technologies

- Optimized Modular Design and Flexible Platforms

- AI and Edge Computing Integration

- Next-Gen Motors and Propellers

- Green Manufacturing and Complex Designs

- Suitable CAD Software for Modern Drone Design

- Essential Skills for Drone R&D and Design Teams

- The Role of Class A Surfacing, Reverse Engineering, Generative Design, and All-in-One CAD in Drone Development

- PSH Design’s Expertise and Strength in Multi-Industry Drone Design

- Frequently Asked Questions (FAQ)

- Contact PSH Design for Professional Drone Design Consulting

1. Introduction

The advancement of drones is revolutionizing numerous sectors—from consumer applications and logistics to military and aerospace. Creating state-of-the-art drones with high performance requires overcoming significant technical barriers and continuous innovation in materials, energy sources, control systems, and manufacturing processes. PSH Design is a leading provider delivering optimal drone design solutions to businesses and individuals worldwide.

2. Key Challenges in Modern Drone Hardware Design

Optimizing Weight – Durability – Performance

- Achieving a lightweight design extends flight time and increases payload, but must not compromise the frame’s strength and critical components.

- The main challenge is the lack of a comprehensive material that is lightweight, durable, and cost-effective.

- Production using composite and carbon fiber materials is costly and difficult to modify rapidly.

- Limitations of Battery and Power Sources

- Conventional Li-Ion and Li-Po batteries provide limited energy density, supporting only 20-60 minutes of flight time for most drones.

- Increasing battery capacity results in heavier weight, creating a vicious cycle affecting flight efficiency.

Payload Capacity and Modular Flexibility

- Versatile drones require multiple modules (sensors, cameras, cargo), but over-modularization can reduce frame stiffness and overall durability.

Sensor and Control Circuit Reliability

- Modern sensors like IMUs, GPS, cameras, LiDAR must withstand vibrations, temperature fluctuations, and electromagnetic interference.

- Tiny components are vulnerable and require protective packaging, raising costs.

Production Costs – Design Freedom – Scalability

- Innovation is costly using traditional molds and tooling.

- Large-scale production of specialized drones demands new manufacturing processes optimized for cost and speed.

Stability of Drive Systems

- Motors, propellers, and servos must operate with high precision and durability at high speeds, controlling vibrations and heat dissipation.

Table: Main Hardware Design Challenges and Solutions :

| Challenge | Description | Common Solution |

|---|---|---|

| Weight vs. Durability | Lightweight for longer flight, but needs strength | Advanced materials, composites |

| Battery Limitations | Limited flight due to energy density | Battery technology innovation |

| Payload & Modularity | Add-ons reduce strength and efficiency | Modular, structural frames |

| Sensor Reliability | Sensors need protection, precise data | Isolated housing, robust circuits |

| Production Costs & Scalability | High cost for rapid design changes, scaling is hard | 3D printing, digital mold tech |

| Drive System Stability | Motors/props need precision; overheating/vibration | Cooling, balanced motors/props |

3. Future Solutions and Innovations in Materials and Technology

New Materials and Advanced Manufacturing

- Utilizing nano-composites (graphene, next-gen carbon fiber) and 3D printing (SLS/FDM) to reduce weight, customize designs, and accelerate development.

Next-Generation Battery Technologies

- Investing in solid-state, hydrogen, and hybrid ultra-capacitor batteries to greatly increase energy density and reduce fire risks.

Optimized Modular Design and Flexible Platforms

- Standardized slot-based frames enable “hot-swapping” of sensors and cargo boxes, vital for rescue, military, and logistics drones.

AI and Edge Computing Integration

- Mini AI processors enhance automation, object detection, and flight optimization even with limited hardware resources.

Next-Gen Motors and Propellers

- High-performance brushless motors, self-lubricating bearings, variable-geometry propellers, and even mini-turbojets for specialized drones.

Green Manufacturing and Complex Designs

- Advanced 3D printing and thermoforming reduce cost while enabling ultra-light and complex geometries.

Table: Future Innovations in Drone Technology

| Category | Key Innovation | Expected Benefit |

|---|---|---|

| Materials | Nano-composites, graphene, advanced carbon | Ultralight, ultra-strong, easier to fabricate |

| Battery | Solid-State, Hydrogen, Hybrid Capacitors | Longer flights, safer, faster charging |

| Modularity | Slot-based frames, hot-swapping | Fast mission changes, improved durability |

| AI Integration | Edge computing, micro AI chips | On-board processing, autonomy |

| Motors & Props | Variable-pitch, mini-turbojets, lubrication | Higher efficiency, reliability, performance |

| Green Manufacturing | 3D printing, eco-materials | Low waste, affordable, intricate shapes |

4. Suitable CAD Software for Modern Drone Design :

| Criteria | CATIA | SolidWorks | Fusion 360 | Siemens NX |

| Large Assembly Handling | Excellent | Good | Fair | Excellent |

| Complex Surface Design | Excellent | Fair | Good | Excellent |

| Comprehensive Simulation | Excellent | Good | Good | Excellent |

| User Friendliness | Medium | High | Very High | Medium |

| Licensing Cost | Very High | Medium | Medium | Very High |

- CATIA and Siemens NX: Best for large, complex projects managing diverse materials and modules.

- SolidWorks: Suitable for SMEs, startups, and practical drone product development.

- Fusion 360: Ideal for rapid prototyping and creative design with integrated AI simulation in the cloud.

5. Essential Skills for Drone R&D and Design Teams

- Proficiency in CAD/CAE/CAM: 3D modeling, stress, thermal, vibration, and crash simulation.

- In-depth knowledge of advanced materials: composites, 3D printing, nanomaterials, and tooling technologies.

- Electronics and mechatronics: optimizing PCB design, sensor integration, and drive system engineering.

- Optimization and simulation capabilities: CFD, topology, aeroelasticity.

- Multidisciplinary thinking: software, hardware, AI control, and IoT data integration.

- Project management and collaboration: efficient team coordination and data version control.

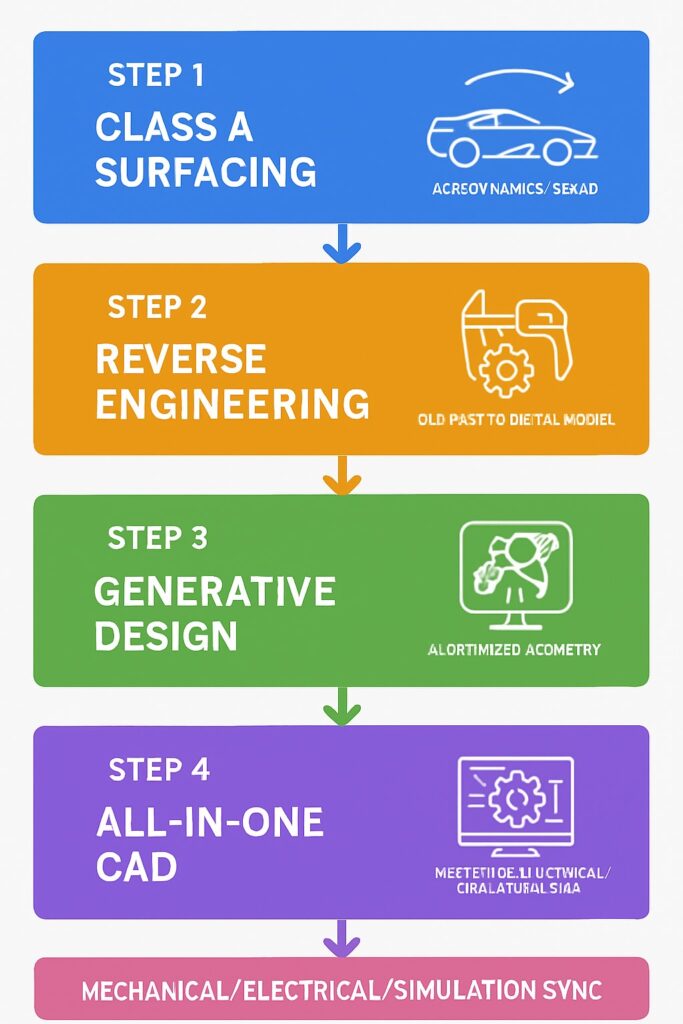

6. The Role of Class A Surfacing, Reverse Engineering, Generative Design, and All-in-One CAD in Drone Development

- Class A Surfacing: Delivers high-quality aerodynamic surfaces improving stability, performance, and aesthetic branding.

- Reverse Engineering: Allows 3D model recreation from existing parts, accelerating redesign and upgrades.

- Generative Design: Uses AI algorithms to create optimized lightweight and durable structures, cutting costs.

- All-in-One CAD: Synchronizes mechanical and electrical designs, integrated simulation, centralized data, and streamlined production.

7. PSH Design’s Expertise and Strength in Multi-Industry Drone Design

PSH Design excels in delivering:

- Precision Class A Surfacing for superior aesthetics and aerodynamics.

- Efficient Reverse Engineering for rapid product iteration and enhancement.

- Cutting-edge Generative Design that innovates lightweight, high-strength drone structures.

- All-in-One CAD solutions enabling seamless coordination of mechanical, electrical, and embedded system designs.

Our experienced engineers leverage the latest technology to provide drone design solutions that optimize performance, manufacturing readiness, and market competitiveness globally.

8. Frequently Asked Questions (FAQ)

Q: What distinguishes consumer drones from military drone hardware design?

A: Military drones are built to meet stricter requirements in terms of materials, endurance, payload capacity, and resistance to vibration. In contrast, consumer drones focus more on affordability, user-friendly features, and ease of maintenance.

Q: Is it worthwhile to invest in integrated Generative Design development?

A: Yes. Integrated CAD solutions help reduce communication errors between different teams, speed up the development process, and enhance overall quality control, making them a valuable investment for drone projects.

Q: What additional skills should drone R&D teams develop beyond technical expertise?

A: In addition to technical knowledge, R&D teams should strengthen their skills in project management, cross-disciplinary collaboration, creative problem-solving, and continuous learning to stay updated with new and emerging technologies

9. Contact PSH Design for Professional Drone Design Consulting

Planning a drone project and need:

- Ultra-lightweight, durable frame design?

- Comprehensive simulations and structural analysis?

- Industry-leading Reverse Engineering and Generative Design?

Contact PSH Design today for free consultations and experience top-tier drone design solutions tailored for your success—from concept to final assembly.

Link of contact : https://pshdesign.com/rfq-free-test-project/

( PSH Design Team )