3D Reverse Engineering in 2025: Precision, Innovation, Impact

What Is 3D Reverse Engineering and Why It Matters in 2025?

3D reverse engineering is the cutting-edge process of capturing precise 3D data from physical objects using state-of-the-art scanners, then converting this data into detailed digital CAD models. This technology empowers manufacturers, designers, and engineers to recreate legacy designs, improve existing products, and accelerate innovation—especially when original CAD data is missing.

In 2025, 3D reverse engineering plays a pivotal role in the digital transformation of industries worldwide, offering benefits such as:

-

Unmatched precision and speed through modern 3D scanners

-

Reduced product development times and costs

-

Seamless integration with AI-driven design tools and advanced CAD/CAE software

-

Enhanced ability to customize and iterate designs

Its superiority over traditional measurement and modeling methods lies in enabling accurate digital twins and transforming legacy products into adaptable assets for ongoing innovation.

Top 3 of 3D Scanners of 2025 for High-Precision Reverse Engineering and Industrial Product Design

In 2025, 3D scanning technology has become indispensable in reverse engineering and industrial product design, offering manufacturers and engineers the ability to capture intricate details with remarkable accuracy. Choosing the right 3D scanner is critical to ensure that designs accurately reflect the physical parts, especially when recreating legacy components or designing complex new products.

Here are the Top 3 3D scanners in 2025 that stand out for their high accuracy, reliability, and industrial design capabilities:

1. KSCAN-X by SCANOLOGY

The KSCAN-X handheld laser scanner leads the market in precision scanning for large and complex industrial components. With an accuracy of up to 0.03mm, it is perfect for reverse engineering intricate machinery parts and heavy equipment. The scanner’s wireless design and robust tracking system allow flexibility in scanning large objects onsite without constraints.

Key Features: Ultra-high accuracy, large working volume, wireless operation, excellent for aerospace and automotive industries.

YouTube Demo: KSCAN-X Scan Demo

2. Creaform HandySCAN BLACK Elite

Renowned for its industrial-grade precision, the HandySCAN BLACK Elite delivers up to 0.025mm accuracy. Its laser triangulation technology allows fast, detailed captures, ideal for reverse engineering small to medium industrial parts with complex geometries. It seamlessly integrates with major CAD platforms, accelerating workflows from scan to design.

Key Features: High-speed scanning, exceptional accuracy, portable, supported by robust software.

YouTube Demo: HandySCAN BLACK Elite Demo

3. EinScan HX Hybrid Blue Laser & LED Scanner

The EinScan HX combines blue laser and LED structured light scanning techniques to capture tough surfaces and fine details with 0.04mm accuracy. This hybrid technology is flexible enough to handle reflective, dark, and complex materials, making it a versatile choice for industrial designers and reverse engineers.

Key Features: Hybrid scanning that handles diverse surfaces, excellent detail capture, affordable for industrial use.

YouTube Demo: EinScan HX Review

Why These Scanners Are Best for Reverse Engineering and Industrial Design

-

Precision: With tolerances between 0.03mm to 0.025mm, these scanners ensure highly accurate digital representations.

-

Versatility: Their ability to scan diverse materials and complex shapes meets the varied demands of industrial design.

-

Integration: Compatibility with leading CAD software enables smoother transition from scan data to detailed product design.

-

Mobility: Handheld or portable features allow onsite scanning for large or fixed parts, improving project efficiency.

Software Innovations: Geomagic Design X vs Polywork in 2025

Among reverse engineering design tools, Geomagic Design X leads in delivering high-fidelity parametric CAD models essential for engineering workflows, while Polywork offers flexibility and automation.

| Feature | Geomagic Design X | Polywork |

|---|---|---|

| Native parametric CAD export | SolidWorks, CATIA, NX, Inventor | Supported but limited parametric editing |

| Mesh-to-CAD conversion | Precise and editable feature tree | Basic surface editing, fewer parametrics |

| Scanner compatibility | Broad (Creaform, Faro, etc.) | Good scanner integration |

| Surface modeling | Advanced automotive-grade quality | Intermediate surface tools |

| Usability | Intuitive, workflow-driven | Extensive scripting options |

Geomagic Design X’s strength in Native parametric CAD export makes it ideal for industries demanding perfection.

Laser Scanning and 3D Metrology: Ensuring Quality Control

In precision manufacturing, laser scanning integrated with reverse engineering enhances 3D metrology—enabling accurate measurement and quality management.

Leading software like Geomagic Control X offers:

-

Comprehensive device support (including scanners and CMMs)

-

Real-time GD&T analysis and deviation reporting

-

Advanced inspection workflows that improve compliance and reduce production errors

Companies in aerospace and automotive industries rely heavily on Geomagic Control X to maintain stringent quality standards.

YouTube referent video :

Real-World Application Examples of 3D Reverse Engineering

Case Study 1: SHINING 3D Scanners Empower Mining Equipment Supplier GL Equipamentos

GL Equipamentos in Brazil transforms its reverse engineering process by adopting SHINING 3D scanners, including EinScan HX and FreeScan UE Series. This upgrade reduced measurement times by threefold, increased accuracy to 0.02mm, and enabled rapid design and manufacturing of complex mining parts previously unmanageable with manual methods. This exemplifies how advanced 3D scanning dramatically improves efficiency and quality in heavy industry.

Case Study 2: SCANTECH’s TrackScan Sharp Optimizes Aerospace Component Inspection

SCANTECH’s TrackScan Sharp high-precision 3D scanner is used in aircraft engine maintenance to replace traditional fixtures. Its no-marker optical tracking accelerates inspection times while maintaining volumetric accuracy better than 0.05mm, helping aerospace companies reduce downtime and costs.

Case Study 3: Automotive Innovation with Artec 3D Scanning Solutions

Hyundai employs Artec Spider II and Leo scanners to deliver custom vehicle part scans that enable rapid prototyping, design tweaks, and quality control — showcasing how 3D reverse engineering integrates seamlessly into automotive workflows for faster product cycles and innovation.

The Imperative of Negative CAD Files for Client Collaboration

A core deliverable in reverse engineering projects is high-quality negative CAD files compatible with software like SolidWorks, Inventor, CATIA, and NX. These files enable customers to continuously:

-

Modify and improve designs without rebuilding

-

Preserve design intent via parametric modeling

-

Ensure smooth integration into existing manufacturing pipelines

This capability fosters ongoing collaboration and adapts to ever-evolving product requirements.

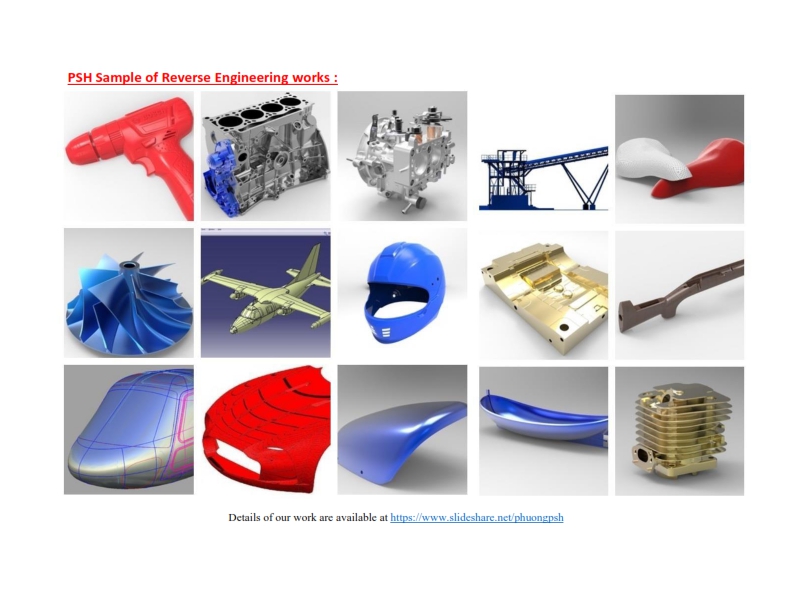

Advanced Class A Surface Design: Industry-Grade Quality

PSH Design specializes in blending traditional reverse engineering with Class A surface modeling, a high-standard technique essential for:

-

Automotive exterior styling

-

Aerospace aerodynamic components

-

Premium consumer products requiring aesthetic finesse

This combination delivers models that are both technically precise and visually impeccable.

Overcoming Challenges with AI and Hybrid Technologies in 2025

The biggest challenges—handling massive datasets and complex surfaces—are surmounted by adopting AI-powered algorithms for:

-

Automatic feature recognition

-

Intelligent scan data cleanup

-

Cloud-enhanced processing power

Hybrid scanning techniques combining laser and structured light enable comprehensive data capture for diverse materials and sizes.

3D Reverse Engineering: The Foundation for AI-Driven Manufacturing

Digitized 3D assets underpin AI applications in:

-

Predictive maintenance and quality forecasting

-

Automated design optimization

-

Real-time factory floor decision-making with digital twins

Investment in 3D reverse engineering today sets the stage for future innovation and competitive advantage.

Why Choose PSH Design for Your 3D Reverse Engineering Needs?

With 15 years of industry experience, PSH Design is a global leader offering:

-

Custom 3D reverse engineering services tailored to client specifications

-

Delivery of native parametric CAD files fully compatible with top CAD platforms

-

Expertise in Class A surface design for automotive and high-precision industries

-

Proven track record working with aerospace, automotive, and industrial machinery manufacturers

Our advanced workflows and design excellence help clients accelerate product development and elevate quality.

Get Started: Free Reverse Engineering Test Project at PSH Design

Discover the value of precise 3D reverse engineering. Send your sample part or CAD request to PSH Design for a free no-obligation test project. Experience firsthand how our expert team and advanced technology can transform your product development.

Contact PSH Design today: https://pshdesign.com/reverse-engineering /

( PSH Design Team )